Breaking Technical Barriers and Crossing the "Dragon Gate" China independently developed high-end CNC machine tools to achieve breakthroughs.

CCTV News:The technical level of high-end CNC machine tools is one of the standards to measure a country’s core manufacturing capability. Last year, China Machine Tool ranked first in the world with an output of 182.3 billion yuan. However, being big but not strong is the biggest bottleneck restricting the development of machine tools in China. How to achieve a breakthrough in high-end machine tool manufacturing? Recently, the reporter from the General Desk worked in the largest R&D and production base of CNC machine tools in China — — General technology Shenyang machine tool was investigated.

This is the user distribution map of Shenyang Machine Tool released this month, covering many key industries such as energy, rail transit, automobile and construction machinery. Thanks to the substantial improvement of core technical indicators, Longmen series of new products have been highly recognized by users. In the past year, Shenyang Machine Tool set up 35 scientific research teams to tackle more than 10 core key technologies such as the design and manufacture of high-end CNC machine tools, and R&D investment accounted for 11.9% of the total sales revenue.

General Technology Dong Lingyun, Director of Strategy and Operation Department of Shenyang Machine Tool:For example, this is a gantry product (schedule). The spindle speed of gantry products has changed from 2,000 and 3,000 rpm to 6,000 and 8,000 rpm. These are the difficulties that have been overcome step by step through a lot of experiments through innovative studios.

Break through 0.01 mm, core key technologies continue to surpass

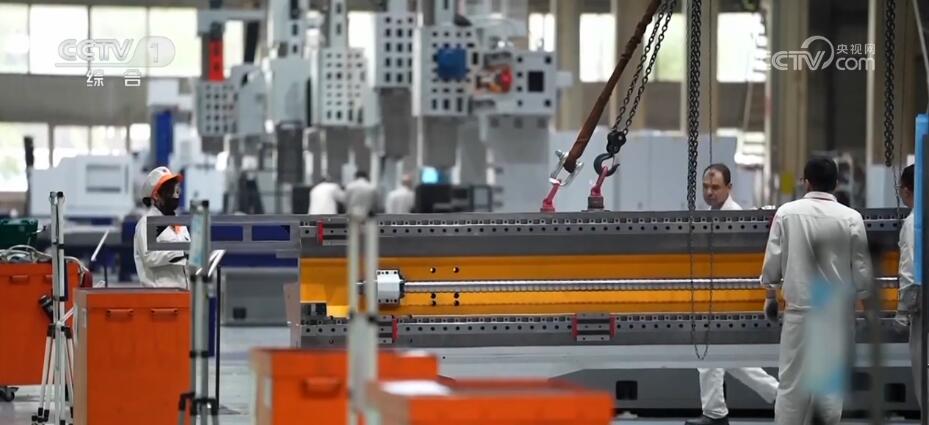

Guide rail is one of the most easily worn core components on machine tools, and its quality directly affects the machining accuracy of machine tools. In the production workshop, Yan Haoming, the project chief engineer of gantry machine tool series products, is testing the guide rail test piece. At present, most domestic quenching technologies can only process parts with a length of 2 meters, but Yan Haoming and his team successfully challenged the quenching of parts with a length of 11 meters.

General Technology Yan Haoming, Project Chief Engineer of Shenyang Machine Tool Gantry Five-sided Machining Center:Why do you want to study this technology? We think the accuracy of gantry machine tools will remain unchanged for a long time, and we must break through the technical barriers to break the blockade of gantry machine tools abroad.

Yan Haoming told reporters that the positioning accuracy of this large-volume gantry machine tool in the world reaches 0.01 mm, which belongs to the precision level. At present, the Longmen series products of Shenyang Machine Tool have successfully crossed the industry threshold of 0.01 mm.

CNC system is the key core component of CNC machine tools, which is responsible for the coordination of various actions during the operation of the machine tools. Some functions of CNC system independently developed by Shenyang Machine Tool have reached the world advanced level.

Headquarters reporter Qi Lili:We see that next to the machine tool is a man-machine interface. By inputting instructions on it, we can operate the machine tool. Although it is a very big iron guy, in fact, its fast moving speed can reach 30 meters per minute, and its positioning accuracy can reach 0.01 mm within the range of 6 meters. For example, it is equivalent to that the moving parts of this machine tool are within 6 meters, and it only takes 12 seconds to move, and the error will be controlled at one tenth of the distance of a hair.

Make up the shortcomings and increase the capacity to help the high-end machine tool industry get rid of difficulties

Shenyang Machine Tool has always been the "vanguard" of China machine tool industry, but many years ago, foreign machine tool industry began to develop and reserve new technologies of high-end machine tools, and China machine tool industry fell into the "low-end trap". In 2018, Shenyang Machine Tool was in high debt and fell into bankruptcy crisis.

In order to help Shenyang Machine Tool out of the predicament, the state, provinces and municipalities have successively issued policy documents to support the reform and development of Shenyang Machine Tool. After reorganization, Shenyang Machine Tool has turned losses into difficulties within three years.

General Technology Dong Lingyun, Director of Strategy and Operation Department of Shenyang Machine Tool:In the industrial chain, we should realize the independence, safety and controllability of the industrial chain and gradually improve the level of localization. Some other products have reached (positioning accuracy) of 0.005 mm, and will move towards the height of 0.001 mm in the future. This is a "dragon gate", and we all have to cross it step by step.